Engineering & Software

Available services include part design, stereo lithography prototypes, quick-turn prototype molds, mold flow analysis, tool design, production tooling, and designing and building test equipment. Seamless communication with our customers is accomplished by using Top Solid, Pro-Engineering, and Mastercam as our main software programs. Other design softwares are also available.

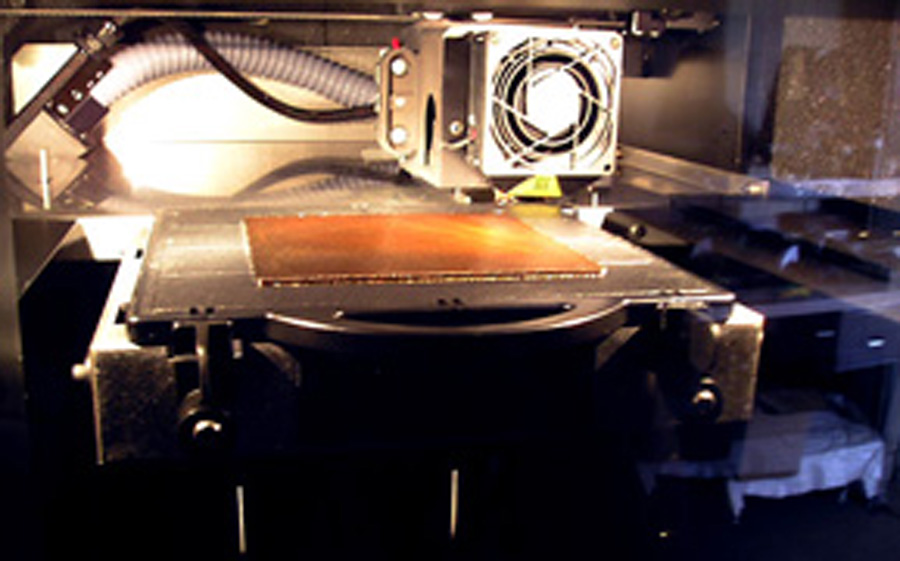

Three-Dimensional Printing

Nothing communicates design ideas faster than a three-dimensional part or model. Fu-Tek has this ability through the process of 3D Printing.

Three-Dimensional printing is a technology that is typically referred to as additive fabrication because the process involves building up the object by adding successive layers.

This process involves providing CAD ED file information to the 3D printer, which then uses that data to incrementally create the part. This is different from traditional subtractive methods such as milling, turning, EDM, etc. Subtractive techniques begin with raw material that is larger that the object to be created and material is removed or carved out to create the object.

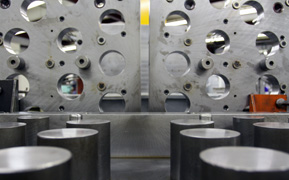

Molding Making & Mold Design

Injection molding's success begins with a high quality production tool. Fu-Tek's precision tooling department features the latest technology in tool-making coupled with countless years of industry experience. Our design team tooling craftsmen design will engineer your tools with the goal of exceeding your requirements. By building the finest tools our mold-making professionals help you meet production goals ranging from single-cavity prototypes, multi-cavity, and hot runner, to three plate and automatic unscrewing production molds. Fu-Tek can also repair your existing molds and prevent future problems. With our exceptional tool maintenance program we will keep your tools running for years.

Machining

Our Machining is second to none. Keeping precision close tolerances and producing precision work is one of our specialties. Utilizing both CNC, and conventional machines, Fu-Tek can assure you they have the correct tooling for your project. Fu-Tek's skilled machinists can bring your projects to life with ease. For your next project, let Fu-Tek give you a price quote by using our "Request Quote" page. Check the list below to see some of the machines that we currently use in our state-of-the-art tooling room.

- CNC Vertical Mills

- CNC Wire EDM

- Surface Grinders (up to 24" x 18")

- Conventional Mills

- CNC Sinker EDM

- Convetional Lathes

- Conventional Drill Press

- Heat Treating (up to 8"x10"x4" blocks)